Robotic process automation for precision liquid handling in the life sciences

Role

Industry

Duration

Problem statement

Liquid handling in life sciences labs is tedious and physically painful work. It's repetitive nature makes it prone to human error. Additionally, it's often handled by highly paid scientists whose time is better spent on other things. Spaero answered the question "how might we automate liquid handling on lab robots?"

Product management

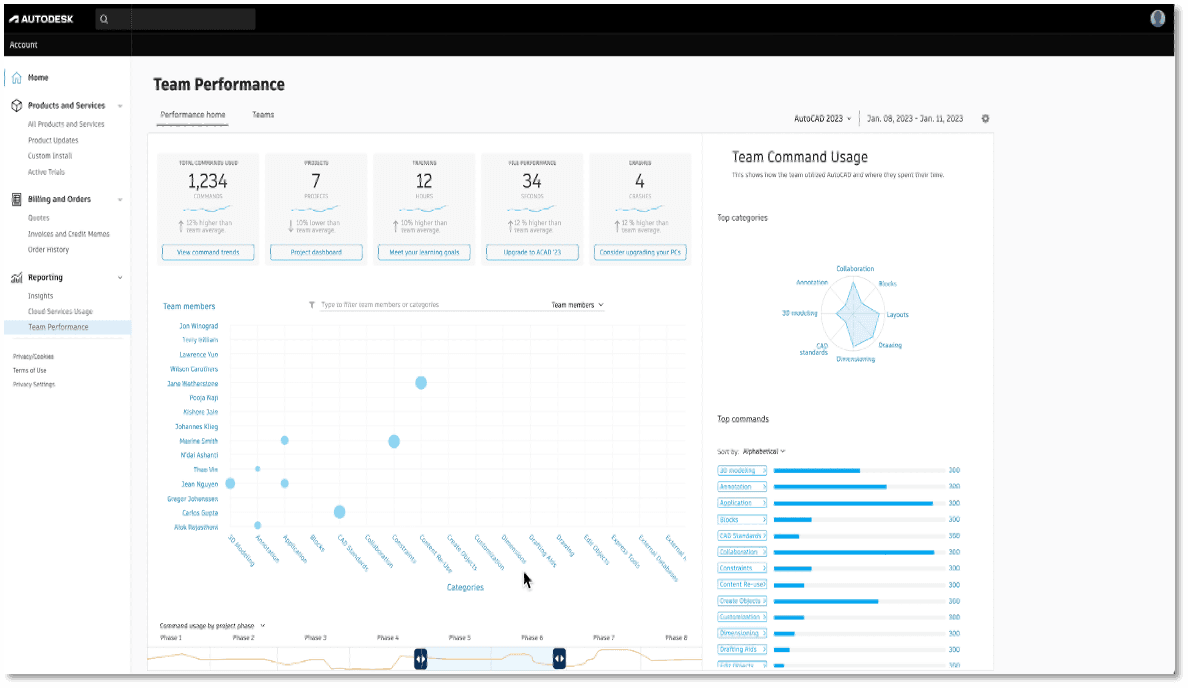

As the companies first employee, I worked closely with the CEO to design the product roadmap, go-to-market strategy and user experience. We envisioned a simple user interface that would allow Scientist users to visually compose experiments such as serial dilutions. The heavy lifting was in interfacing with the liquid handling robots and in understanding the characteristics of the liquids they were handling. For example, the pipettes in the liquid handler as well as the liquids themselves had huge impact on how the liquids could be dispensed. Similarly temperature, humidity and other environmental factors also played a role. Imagine trying to pipette a very precise amount of maple into a test tube. The viscosity makes this quite challenging.

Design strategy

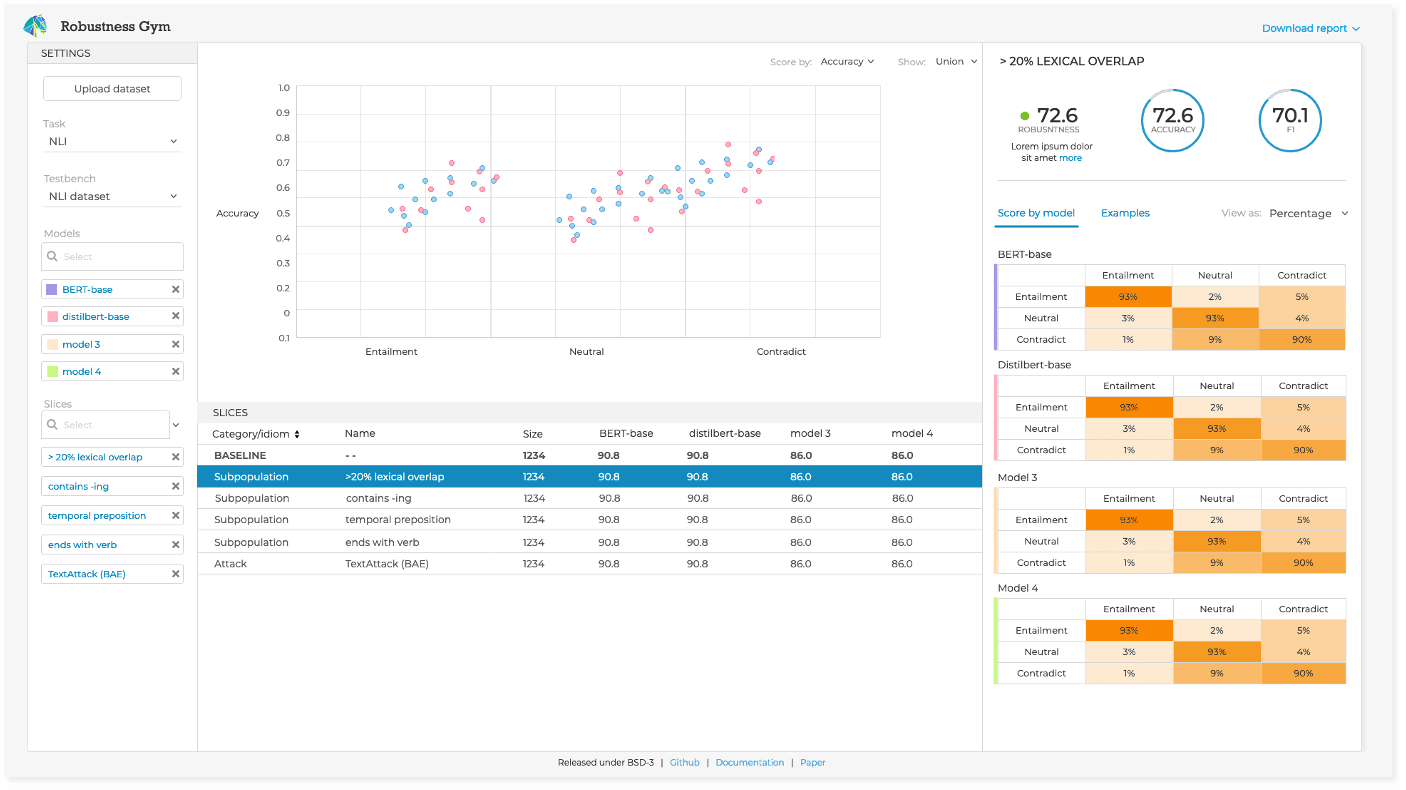

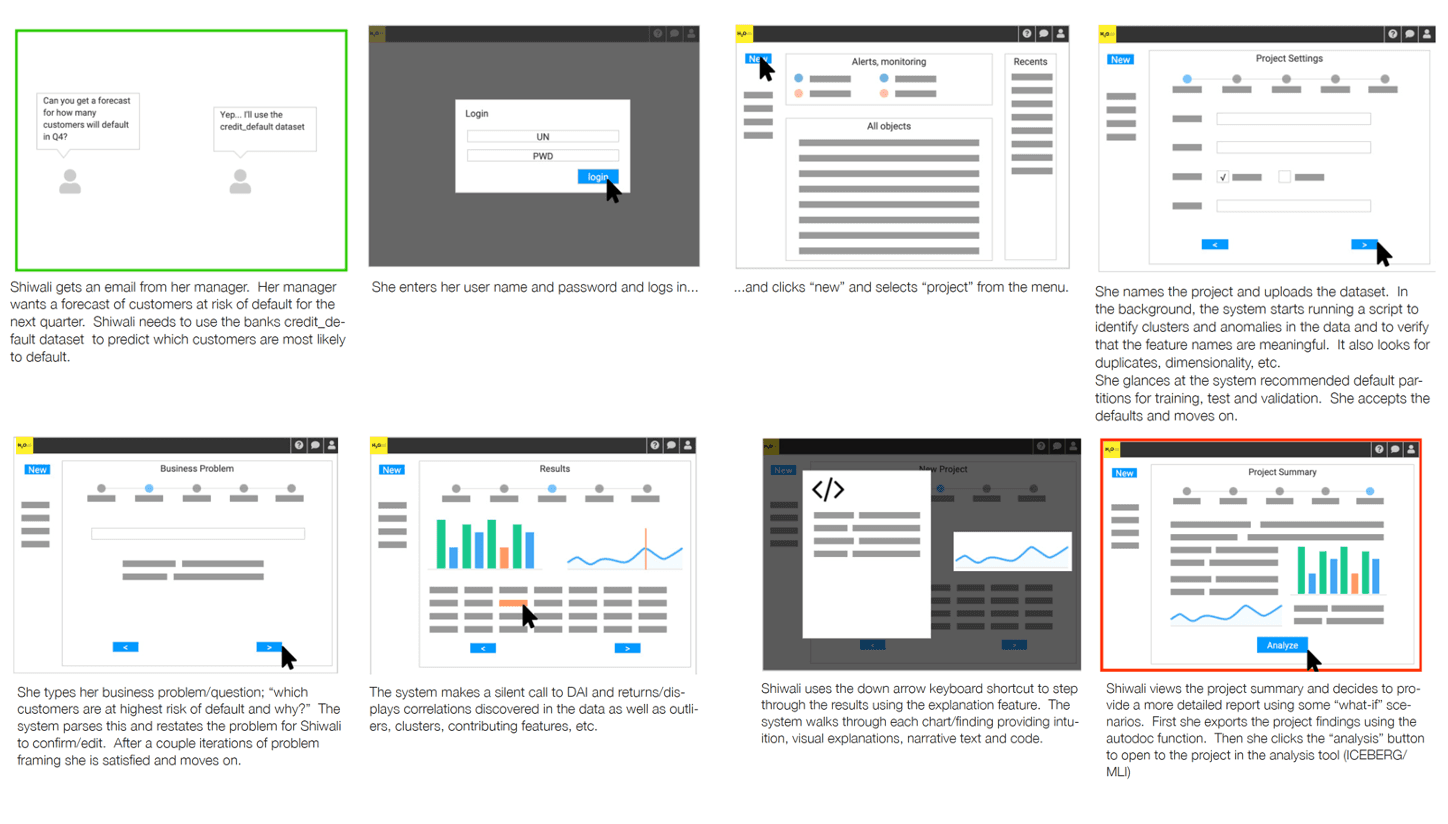

User research: I worked closely with our design partners to observe, understand and document their primary use cases. There was also a lot of work with subject matter experts (i.e. "Robot Whisperers") to understand the capabilities of the target liquid handlers.

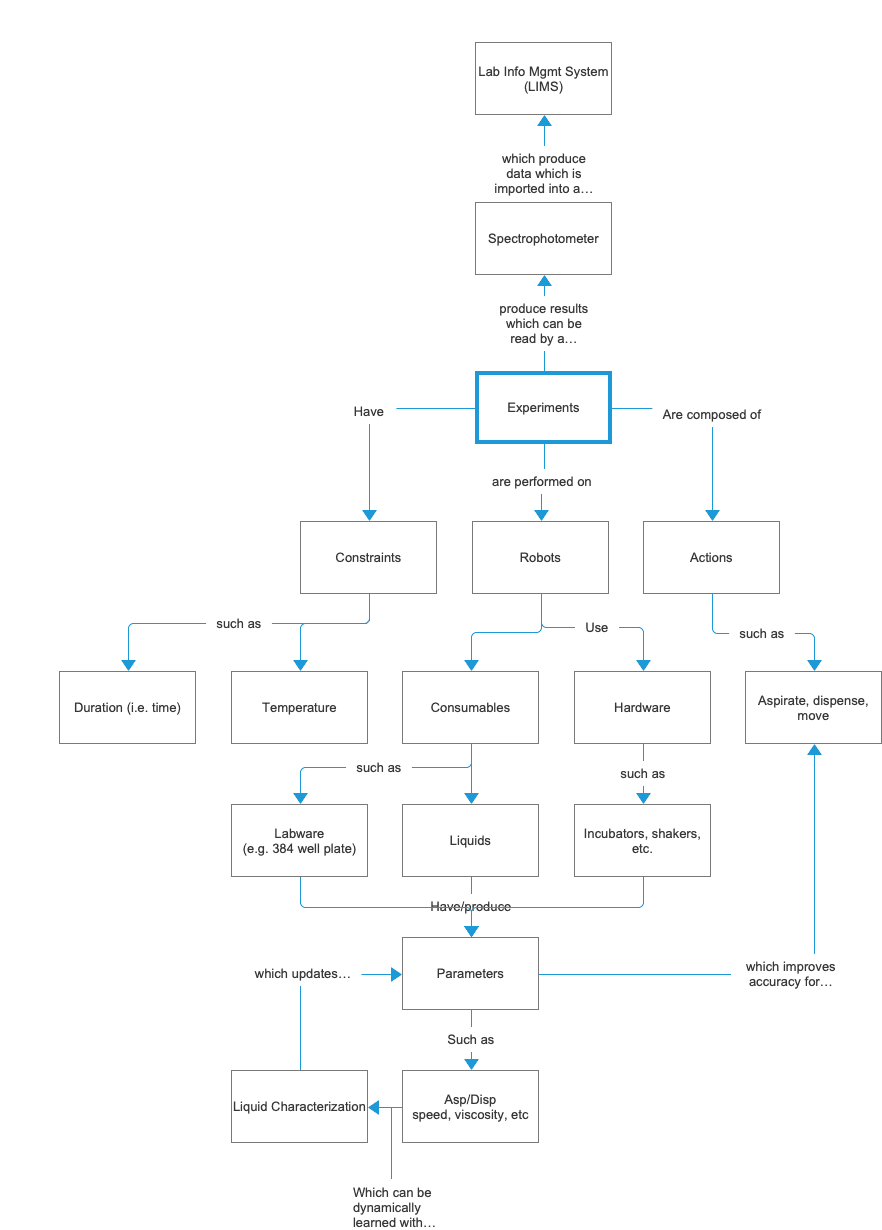

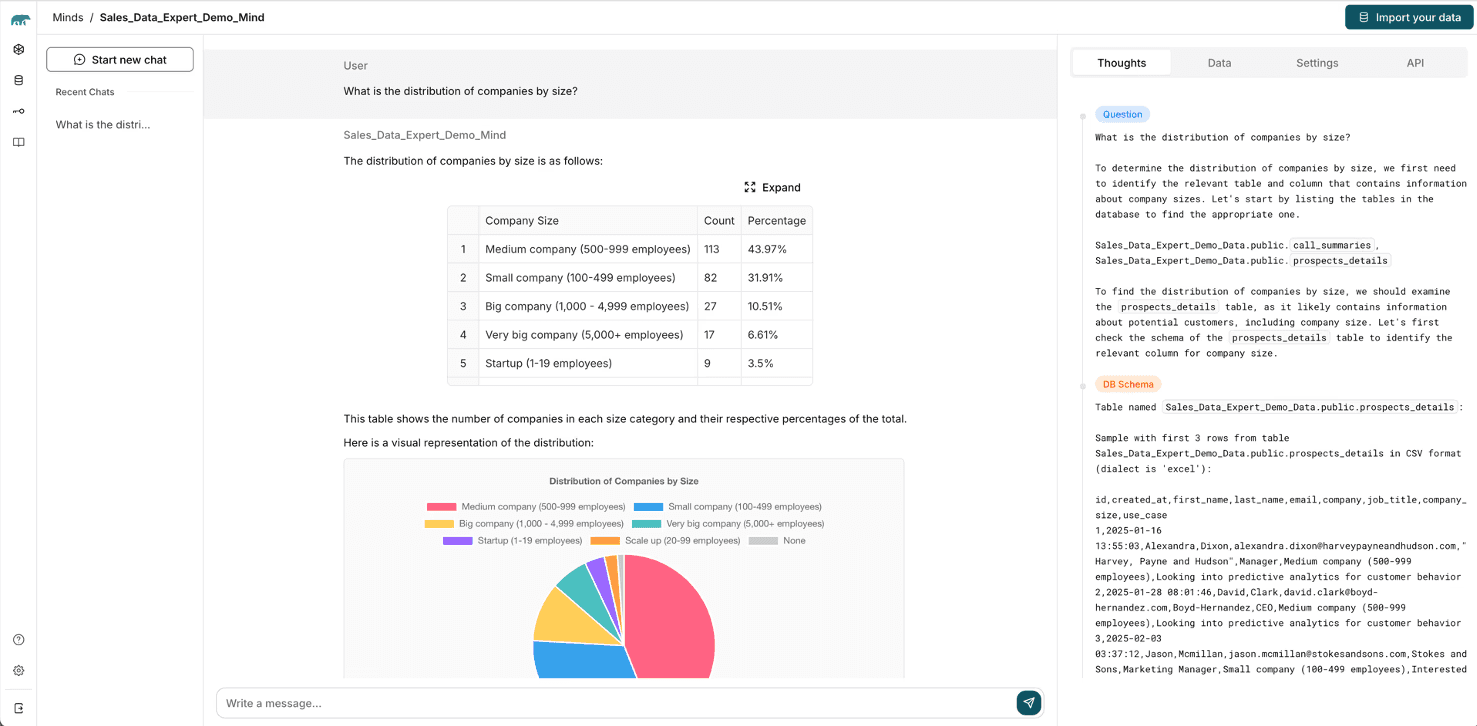

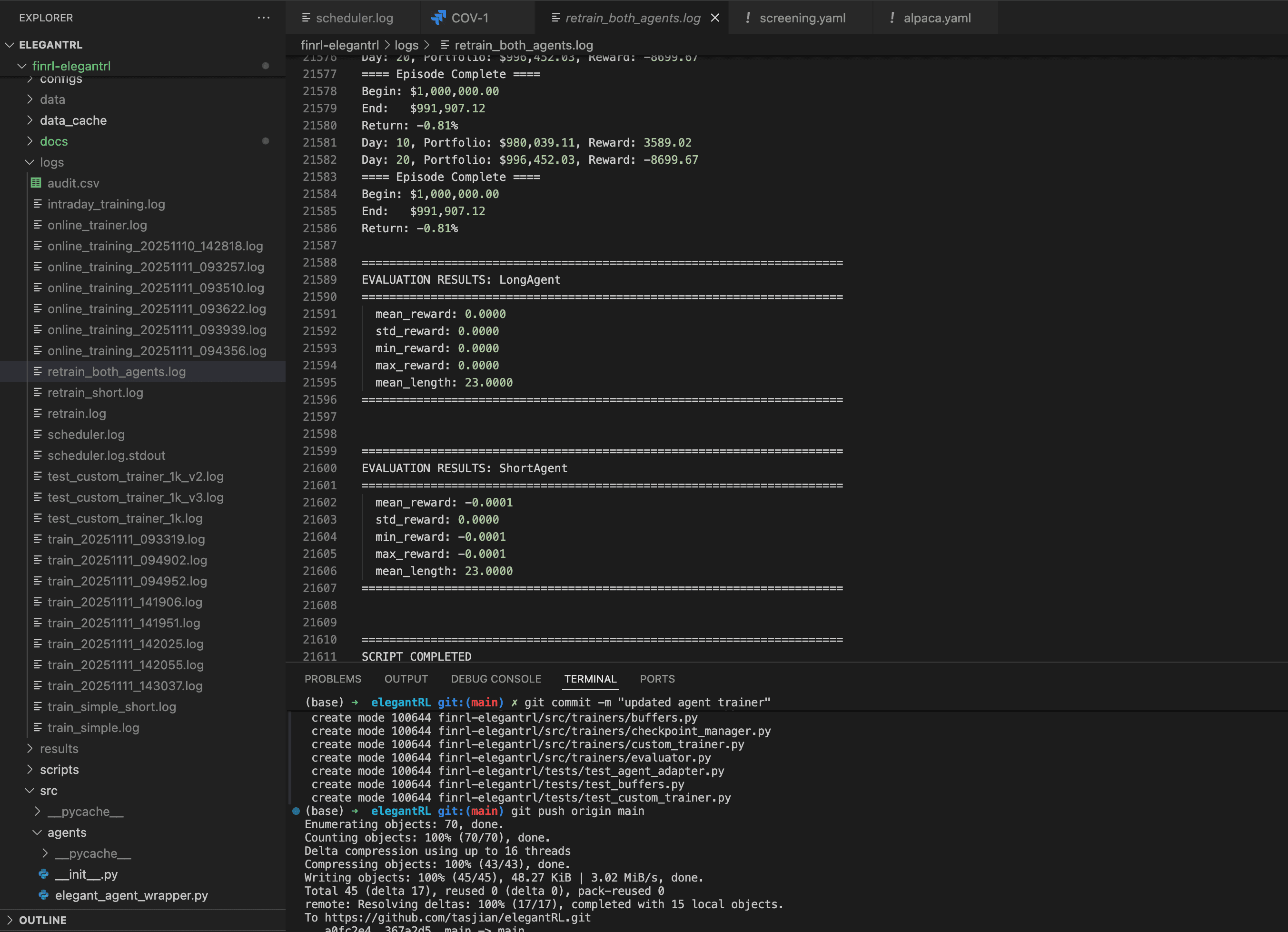

Workflow: It was extremely challenging to outline an MVP since minimally viable meant that most of the required functionality was needed. We started by mapping an end to end user journey and then building an architecture. Our product fit into that architecture and needed to interface with other parts of it. The function composer was the visual interface that allowed Scientists to design and monitor experiments and pipe data back to their lab automation notebook (e.g. Benchling).

High-Fidelity Prototyping: I designed and prototyped the UI using Axure. This UI was complex enough that a design tool primarily focused on UI (i.e. Figma) was insufficient. It was necessary to prototype so that we could test and iterate on the design with our target persona (Scientists).

Challenges

A challenge we faced was determining the right scope for the initial product. The core functionality was needed for the product to be minimally viable, but that was a heavy lift. We also faced challenges in interfacing with various liquid handler robots due to different robot operating systems. Finally, we were limited in the number of liquids we could handle due to the nature and characteristics of the liquids. For example, certain liquid handlers could only achieve a certain level of precision using a given liquid due to physical limitations.